Facing supply chain disruptions, hospitals must shift strategies

Experts say health systems must weigh the costs and the risk of products being unavailable. Hospitals need good data and strong leadership to deal with ongoing challenges.

More than two years into the COVID-19 pandemic, hospitals and health systems say they continue to see supply chain issues.

Hospitals and health systems are employing more strategy in their supply chain management, largely out of necessity. But they could still improve, supply chain experts say.

With uncertainty persisting, hospitals and health systems must look more carefully at where they are getting their supplies and develop contingency plans for disruptions. Experts say hospitals need to be looking more closely at their own data regarding their supplies in order to anticipate demand more accurately.

While hospitals are dealing with

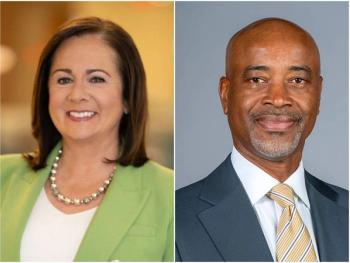

“You know, you may have the best price negotiated or the cost controlled, but if you can't get the product, it does you no good,” Gordon told Chief Healthcare Executive in a recent interview. “So you're starting to see this shift now into the managing of supplies, and being able to understand and really mitigate a lot of the issues that are happening within the organization.”

Healthcare organizations can do better in managing supplies, but he said systems are still spending a great deal of time dealing with ongoing disruptions and supply shortages.

“Is there room for improvement? Absolutely,” Gordon said, but he added, “They're fighting these daily fights, and it's kind of hard to have this strategy in place where you're really trying to deal with that.” (See part of our interview with Michael Gordon in this video. The story continues below the video.)

Better data and demand management

In the past, health systems spent much less time worrying about shipments of medications and other critical supplies. Years ago, hospitals would place orders when they were on the cusp of running out of a drug.

“Before the pandemic, a lot of organizations were just-in-time inventory,” Gordon said.

Since the beginning of the pandemic, organizations have begun stockpiling some critical items. The stockpiling approach helps with availability, but now organizations are also spending more money to store some of these items, in some cases leasing warehouse space.

Still, Gordon projects systems are going to try to maintain ample supplies, given the uncertainties of distribution. “Are these organizations going to continue to have more on hand than they did in the past? I think the answer is yes,” Gordon said.

Health systems are more proactive and looking to place orders before the shelves are bare, said William Weinstein, a partner at McKinsey & Co.

“Systems are doing a better job than they did before,” Weinstein said. “There’s still opportunity to do better.”

Weinstein cited inventory visibility and demand management as key elements of a more resilient supply chain. Organizations need to understand clearly what they have available and how much they expect to use, as well as alternative suppliers for products that can be prone to shortage.

He also pointed out effective governance is the key to successful supply management. Providers that are doing better at managing supplies are having daily or weekly meetings to assess shortages, rather than reacting at the moment of crisis, Weinstein said.

The key to making good decisions is getting data on supply use and trends.

“Whenever you talk to supply chain leaders, at the end of the day data is key,” Gordon said. “Regardless of what you want to do with it, data is the most important thing that supply chain leaders can have and can access to allow for real time actionable decisions.”

Health systems must examine historical data, as well as seasonal trends and patient trends, Gordon said.

Hospitals that are managing supplies without good data are similar to consumers buying cars “without data on the bells and whistles,” Weinstein said.

“You can’t have a conversation without the nuance,” he said.

Knowing the origins

More healthcare organizations are going to be looking at obtaining supplies from domestic sources, or from suppliers that are closer to America, Gordon said.

“I don't think it's going to be an overnight shift,” Gordon said. But he expected healthcare organizations would be shifting more to Mexico or other “nearshore” countries, as well as domestic suppliers.

Healthcare organizations need to know the origin of their supplies as they aim to reduce the chances of running out of essential items. Country of origin is “a huge deal,” Gordon said.

“That's absolutely something that healthcare organizations need to understand now,” Gordon said. “And as we start talking about risk, where are your products being manufactured? And what are the tier two or tier three suppliers or manufacturers within your supply chain?

“Historically, organizations, healthcare systems have just looked at, where do we get the product from? Is it coming from a distributor or manufacturer? They haven't necessarily had to understand well, who's manufacturing it? Where are the raw materials coming from? And now that has been a big deal to figure out where that happens.”

Increasingly, health systems are talking more about getting products from sources closer to home, even if it means paying more, Gordon said.

“The original equation that a lot of organizations looked at was just, what's the cost? And what's the quality of the product? Is it acceptable for patient use? And then how can we get it at the lowest possible cost? That was originally the equation,” Gordon said.

“Now you're bringing in that risk factor of it of, well, what is the risk if we can't get this product? Where is it coming from? What are the shipping delays? … And does it make sense to potentially pay a premium on some of these items, but we're ensuring that we'll have this for patient care.”

Mix of suppliers

Some supply chain experts say hospitals and health systems should consider obtaining supplies from a mix of vendors, rather than relying on just one or two suppliers.

Hospitals often choose one prime supplier to get better pricing and service. Gordon suggests it makes sense for hospitals, especially larger organizations, to have a prime supplier, along with contractual safeguards that there will be some assistance in getting a right product.

Hospitals can also consider having some business with alternative suppliers, in order to have more options if there are disruptions.

Health systems should be asking suppliers what sort of guarantees or assurances they can provide, and what they will do if there’s a shortage, Weinstein said. Health systems can ask how suppliers plan for those disruptions, he added.

Communication is critical

Healthcare executives need to support their supply teams and have a good understanding of what they need, experts advise.

Gordon said he recommends “the executives, the C suite, to really be aligned with your supply chain leaders and make sure that you're providing the support, but also, you know, understanding what the investments look like.”

Supply managers must be communicating with health system executives on trends and risks.

Before surprising the C-suite with spikes in supply costs, it’s imperative to talk about the factors driving the higher expenses. Gordon stressed the importance of getting buy-in from hospital leaders about spending more if needed to get supplies from a closer source with a reduced risk of disruption.

“I also put some of the onus on the supply chain leaders to make sure that a lot of this information is easily accessible to healthcare leaders and executives,” he added.